Modern infrastructure for Cold Storage

India is one of the largest producers of horticulture crops in the world. There is huge wastage recorded or seen at different levels in the entire value chain of the horticultural crops. We need a modern infrastructure for cold storage to reduce post-harvest losses.

The government of India is aiming at doubling the income of farmers. This can be possible only by preventing wastage and adding value to it at different levels in the value chain. Therefore, the government has come up with different schemes to establish required infrastructures from different agencies to encourage people and come forward.

One of the studies of the National Centre for Cold-chain Development (NCCD) conducted in 2016 found that there is a huge gap in cold chain infrastructure, ranging from packhouses at production centers to multi-chamber cold storage infrastructure and distribution hubs at consumption centers. The details are available in the report available on the NCCD website.

The components that fall under cold chain infrastructure would be as under.

| Sr. No | Infrastructure | Components | Remark |

| 1 | Pack House | Sorting, cleaning, grading, packing, precooling. Staging or ripening. | At the production centre. |

| 2 | Cold Storage | Receiving, holding, maintain quality and delivery | Within the vicinity of production clusters. |

| 3 | Multi commodity multi chamber cold storage | Receiving, holding, bulk breaking, distribution | At Consumption centre |

| 4 | Logistic / Transport | Different temperatures for different natures of commodities. | Temperature controlled, insulated and frozen vehicles entire supply chain. |

Cold chain infrastructure projects are easier said than done. Therefore, each component of cold storage needs to be selected very carefully, either the structure of the building, machine, or insulation part of the project.

Following factors are essential in a modern infrastructure for Cold Storage

Building

Earlier civil buildings used to be a part of cold chain infrastructure, however, the same has been replaced with the pre-engineered building (PEB). The PEB can be installed above a wall of a certain height or plinth level as per the requirement.

In the case of a packhouse, it better has a wall with tiles on it, to maintain the cleanliness in the premises. Also, an epoxy coated floor would be a better option instead of other flooring options. An epoxy floor will help in proper cleaning and maintaining hygiene in the area.

The height of the PEB can be raised more than 15 m. This is an advantage for the PEB building that when there is a space constraint to match the desired capacity the building height can be increased till the requirement, subject to height permission and FSI norms of particular location.

Another advantage of having pre-engineered buildings in cold chain-like projects is that these steel structures take 40% to 45% less time for installation as compared to the construction of civil work.

The time saved will give a chance to generate revenue from the project. In case of civil work, the demolition cost is required and cannot be used for the demolished component, however in case of steel building, the unit can be easily dismantled and can be shifted to a new place or can be sold in a scrap too.

In terms of cost, both civil and steelwork will be similar to steelwork and could be sometimes below, as steel rates in the market keep on fluctuating.

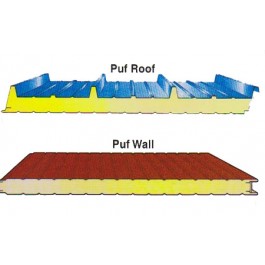

Earlier days in civil infrastructure project thermocol used to be placed in between thin metal sheets and brick walls. However, such type of insulation is not durable and needs to keep on replacing as and when required. Therefore, in modern cold storage projects, PUF panels are being used.

PUF panels are Lightweight, energy-efficient and durable panels. Suitable for diverse applications, PUF panels consist of a rigid core sandwiched between sheet metal structural boards.

PUF insulated sandwich panels integrate joists and studs, insulation, vapor, and air barriers. PUF panels act as a wall to the steel structure and insulated material for cold storage. The width of the PUF ranges from 40mm to 150mm used in cold storage projects.

Capacity – In modern cold storage projects will be beneficial if the same being set up near the consumption centre. As, there would be a requirement of a mixed kind of product range.

Generally, in modern cold storage, the chamber size is small, as multiple products would be required to store, which leads to multiple temperature requirements too.

Therefore, so as to match their temperature requirement and which also reduces the utility cost, small size multiple chambers are generally proposed. As per the national horticulture board, such projects should have a capacity of 250 MT/ Chamber.

The product which is going to be stored must have removed field heat if received from the field. Each product you handle has its own temperature requirement after harvesting at the farm.

However, when the temperature of harvested produce is reduced within four hours of harvesting by means of precooling or any other way of it, the following changes can be achieved.

- Decrease in respiration rate

- Reduction in water loss.

- Sensitivity of ethylene is reduced.

- Microbial development is slowed.

Temperature zones –

| Sr. No | Temperature Zone | Temperature Range | Products stored |

| 1 | Frozen | -5°C to -40°C | Processed food (Frozen, Blast or IQF) |

| 2 | Chilled | +0°C to + 5°C | Apple, Orange, Pear, Grapes, Carrot etc., |

| 3 | Cold/ Cool Storage | +8°C to 15°C | Processed food |

| 4 | Ambient storage | +15°C to 25°C | Chocolate, Powders etc. |

Material handling

Generally, this has been observed in a modern cold storage infrastructure that the material is being placed on the pallet and the pallets on the steel racks.

The height of each shelf of the rack would be kept maximum is 1.50 meter and which holds load up to 750 to 1000 kg material subject to volume of the product. The height of racking can go up to 10 heights vertically.

The standard size of pallet followed is 1000 mm X 1200 mm and 1000 mm X 1300 mm. The types of pallet racking systems have a range of mobile racking, stationery racking and drive in racking system.

However, mobile and drive-in racking are not seen personally anywhere but stationery has been seen in many places. Stationery racking could be single deep or double deep.

The material moment in rack-based cold storage units is done through the rich tricks, which can lift loaded material to 15-meter height and can extend its fork 2 meters.

The turning radius of a rich truck is 3.20 meter, therefore in the case of stationary racking distance between two racks would be a minimum of 3.20 meter.

However, in a single product like potato storing cold storage, the capacity can be of 1000 MT / Chamber or more than that. In single-chambered or big chamber-sized modern cold storage infrastructure, potatoes are directly loaded in the chamber in the loose condition through an extendable loader conveyor to the desired height and stored for a long time.

However, in the case of old infrastructure single commodities are stacked on the mezzanine floor in the cold storage. Mezzanine floors are not permanent structures but have the load-bearing capacity to handle the load of stacked material.

Such floors have made up of wooden or metal strips placed at the desired distance, which helps in circulating cold air throughout all the floors.

Major refrigeration components

Thermostatic Expansion Valve – Before the evaporator, this is located at the end of the liquid line. This is a device that controls the amount of refrigerant that flows to the evaporator.

Evaporator- The sole purpose of the evaporator is to remove the unwanted heat from the product through liquid refrigerants. The liquid refrigerant must be at a low-pressure.

Capacity Control System – As its name might suggest, the capacity control system regulates the power and energy consumption, although it can also manage dehumidification or decrease compressor cycling. The on/off cycling of the compressor is the simplest form of capacity control.

Compressor – In simple terms, a compressor can convert low-temperatures to high-temperatures, which can be the cause of an increase in pressure. Through a compressor, heat can be easily released.

Condenser- This device can extract heat from the refrigerant. Fans placed above the condenser unit draw air over the condenser coils.

Receiver– As temporary storage and a surge tank for liquid refrigerant, the receiver acts as a vapour seal. With the primary purpose of preserving the vapour moving down the liquid line to the expansion valve, receivers can be made for both horizontal and vertical installation.

Note

The reviews expressed above are from personal experience, standards guidelines, and other secondary sources of the writer and can be different from other expert opinions. I hope that with the right government policies, its seamless implementation and modern infrastructure for cold storage we can reduce post harvest loses to a substantial level.

You may be also be interested in