Microalgae for Plant-Based Meat

Algae are a good source of essential amino acids, minerals found in meat, omega-3 fatty acids found in fish, and other nutrients that vegetarian diets lack. The researchers believe that algae could be utilized in plant-based meat substitutes.

Particularly, the algae spirulina and chlorella were among the first food supplements and food coloring to be introduced to the market. Algae are a fantastic source of protein, which has greatly expanded the possibilities for making vegan food and meat substitutes in a broad sense.

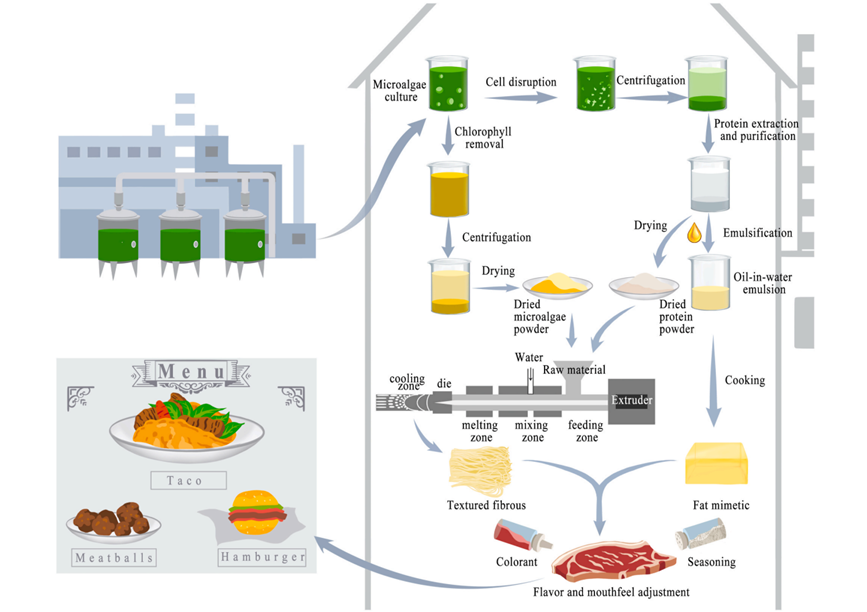

Plant-based meat aims to duplicate or outpace animal-based meat’s nutritional profile as well as the entire consumer experience, including its organoleptic qualities, consistency, and familiarity in everyday meals. It takes sophisticated knowledge of the intricate interactions between constituents to formulate these products.

In an effort to reduce or perhaps eliminate the rising demand for meat consumption, meat analogues have recently been produced as a healthier and more environmentally friendly substitute. A promising element for meat substitutes is suggested to be microalgae, a novel protein source.

The Potentials and Challenges of Employing Microalgae as an Ingredient to produce Meat Alternatives

Advantages

- From a nutritional standpoint, microalgae are promising prospects to produce vegan meat. The food industry may be able to manufacture meat analogues with superior nutritional value thanks to high protein content and also the presence of a multitude of nutraceutical components.

- The use of bioactive substances found in algae in meat products. Algae’s bioactive components can provide meat products with functional properties like antioxidant, neuroprotective, and anti-genotoxic, providing for healthier eating.

- Algae addition to foods can also help delay microbial deterioration and improve shelf life.

- Other algae-based applications, such as for packaging materials for meat products, are being investigated.

Difficulties

- The technological pathway is a major barrier to the production of meat substitutes made from microalgae. The texturing processes for converting microalgal biomass to meat analogues are still in their infancy and need more research.

- Another area to research is the pre-treatment of raw ingredients to get rid of undesirable odor and color.

- The production of microalgae is also constrained economically by infrequent scaling-up and ineffective processing methods, although these issues can be resolved by using a variety of cultivation techniques.

- Consumers’ dietary habits as well as their understanding have an impact on whether they adopt new products, specifically those containing algae.

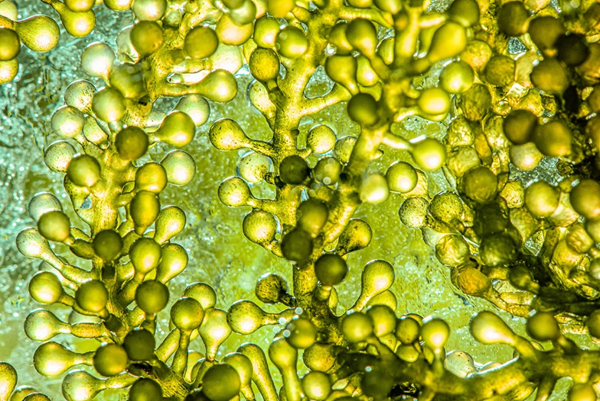

Chlorella Vulgaris

One of the most widely grown algae in the world, Chlorella vulgaris is used extensively in a wide range of applications. Chlorella vulgaris has a high chlorophyll content, is protein-rich, has all the essential amino acids, and has a lipid profile with 60% polyunsaturated fatty acids. Additionally, this microalga is a good source of calcium, iron, potassium, phosphorus, vitamin B12, and other vitamins and minerals.

Approvals and Applications of Chlorella Vulgaris

- Chlorella vulgaris has been designated as Generally Recognized as Safe (GRAS) by the US Food and Drug Administration (FDA) and listed in the EU Novel Food Catalogue for Food Applications by the European Food Safety Authority (EFSA).

- The Natural Health Products Ingredients Database (NHPID) of Canada and the Australia Therapeutic Goods Administration (TGA) both list chlorella vulgaris as an active and excipient ingredient in listed medicines.

- Additionally, the EU Cosmetic Ingredients (CosIng) database and the Inventory of Existing Cosmetics Ingredients in China both approve of chlorella vulgaris powder as a cosmetic ingredient.

Allmicroalgae produces Autotrophic Chlorella Vulgaris (Premium Chlorella) and Heterotrophic Chlorella Vulgaris (Smooth Chlorella, Honey Chlorella, and White Chlorella)

Premium Chlorella vulgaris

Smooth Chlorella vulgaris

Light-green smooth Chlorella is made in a fermenter container, in the dark. As a result, the reduction in chlorophyll content leads to a lighter color and milder taste. This microalga’s organoleptic characteristics are enhanced through heterotrophic cultivation, which is more effective and allows for strict control without compromising the nutritional profile.

Honey Chlorella vulgaris

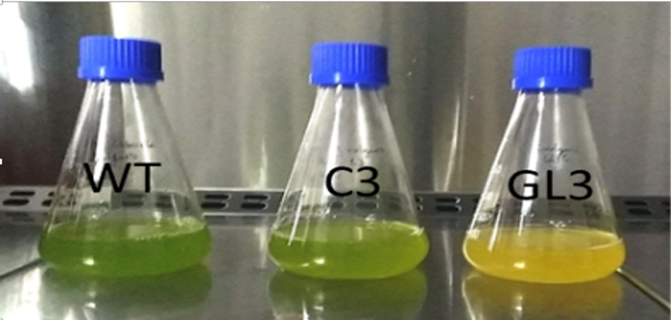

Yellow Chlorella vulgaris is produced by isolating lighter strains under stressful conditions. This non-GMO modification is frequently employed to accelerate naturally occurring selection. A stable strain with similar productivity and reduced chlorophyll content—which results in a milder flavor and odor—as well as no additives or preservatives—makes up the finished product.

- It has a protein content of almost 35% by dry weight, which comprises all the essential amino acids. Omega-6 and omega-9 make up the majority of the 7% total fatty acid content, and there is plenty of fibre present. This strain also includes added-value components including the naturally occurring pigment lutein and a wide range of vitamins and minerals, including phosphorus, zinc, and vitamin B12.

White Chlorella vulgaris

White Chlorella vulgaris is produced similarly to Honey Chlorella by using lighter strains under stressful conditions. It has a moderate flavor and odor and can be used as a vegan or vegetarian alternative ingredient. It is abundant in protein, fibre, and polyunsaturated fatty acids, just like chlorella.

- It contains high fibre content, a low lipid profile, and includes more than 40% protein by dry weight, including all essential amino acids. In addition, it includes valuable substances such as a variety of vitamins and minerals as well as the natural pigment phytoene.

White Chlorella, which can replace traditional dairy bases like milk, and Yellow Chlorella, which functions well as an egg alternative.

ProFuture and AllMicroalgae collaborate on new and lighter Chlorella strain

ProFuture has partnered with Marbiotech/CCMAR Group, Greencolab at the University of Algarve in Portugal, and Allmicroalgae to create a brand-new, enhanced Chlorella strain.

Despite the fact that foods made from microalgae already exist and are of a high caliber, essential improvements must be made to existing microalgae-based foods because customers do not usually prefer foods with organoleptic qualities like a “grassy” taste, an intense green hue, or a fishy odor.

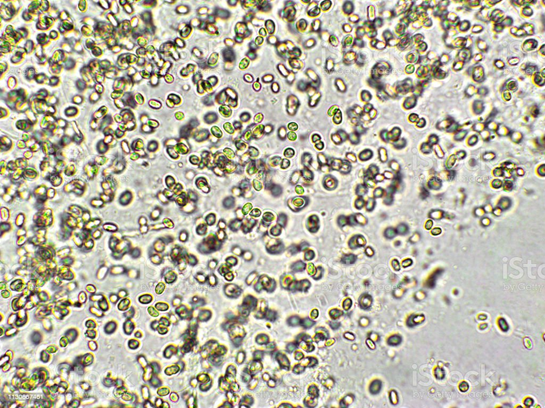

ProFuture addressed this in 2022 with a collaboration on innovation. To enhance the quality of the produced biomass and consumer acceptance, novel strains of three microalgal species—Chlorella vulgaris, Spirulina, and Tetraselmis (Tetraselmis chui and Tetraselmis striata) were selected. Random mutagenesis is the process; while mutations can arise naturally through natural processes, they can also be artificially produced using laboratory operations, separating microalgae strains with different features.

The New Chlorella: High-Protein Content and Improved Organoleptic

First, the C3 and GL3 strains of Chlorella were discovered. In comparison to wild-type (WT) microalgae, C3 can grow on solid media significantly quickly.

- It’s interesting that while GL3 cells had higher protein contents than WT cells and considerably different amino acid profiles from C3 cells, they also displayed vestiges of chlorophyll, lower amounts of carotenes, and higher protein contents than C3 cells.

- Other strains of Chlorella have not been found to have glutamic acid in the same concentrations as soy and spirulina.

- Additionally, the GL3 cells outperformed the WT in terms of cell concentration, strongly indicating that they could eventually serve as a source of protein that can be produced on a bigger scale.

Upscaling through Collaboration and Food trials

Allmicroalgae Natural Products, a Portuguese producer of microalgae, has recently scaled up a new high-protein microalgae strain developed by researchers. The scale-up is part of the EU-funded Microalgae Protein Ingredients for the Food and Feed of the Future (ProFuture) project. Producing vegan food with the new chlorella strain could result in better-tasting, more nutrient-dense foods.

The goal of ProFuture is to develop low-cost, environmentally friendly microalgae production technologies that can provide wholesome, sustainable meals and feeds that are packed with protein. Microalgae are among the most promising option for supplying the world’s rapidly expanding population with food due to their high nutritional content and low carbon footprint

Allmicroalgae scaled up the production of the new Chlorella at their facilities and sent it to the German Institute of Food Technologies (DIL e.V.), the Institute of Agrifood Research and Technology (IRTA) in Spain, and ILVO – Institute for Agricultural and Fisheries Research in Belgium.

The new Chlorella capabilities to evaluate the behavior of this unique ingredient in food applications are under the control of ILVO.

Based on these findings, IRTA and DIL work with food producers to refine palatable and healthful formulas using the new chlorella. The biggest difficulty lies in creating innovative products (vegan sausages, snacks, soups and vegetable creams, sports drinks, bread, and pasta) with enhanced nutritional value and engaging sensory attributes.

Giving priority to safety analysis, which included analyses on heavy metals, probable allergens, microbiological stability, polycyclic aromatic hydrocarbons (PAHs), acrylamide and cytotoxicity assays, and possible pesticide residue. In September 2023, the 4-year ProFuture initiative will come to a close. New Chlorella-based foods will be thoroughly defined from a biochemical, technological, and sensory standpoint. The finest recipes will then be scaled up by food manufacturers and tested for market acceptance.

Start-ups/ Companies Innovating with Algae for Vegan Meat Alternatives

- Sophie’s BioNutrients has launched its first 100% plant-based hamburger patty made from single-cell microalgae, which boasts more protein than beef or the majority of fish. Also, they developed the world’s first 100% microalgae-based milk alternative.

- Terramino Foods is redefining seafood by utilizing fungi and algae to produce toxin-free, cost-effective products. A “salmon” burger created from fungi and algae was Terramino Foods’ initial release.

- Triton Algae Innovations is getting ready to introduce its plant-based algae ingredients and its first retail product- a vegan tuna substitute.

- Smallfood is introducing a novel strain of microalgae that is cultivated using their specialized fermentation technique in just seven days and yields a novel “perfect protein” that can be used to make vegan meats.

- Trophic is on a path to build seaweed the most accessible and effective source of protein, replacing soy.

- Plantruption burgers produced with hand-harvested Irish seaweed, microalgae, and tempeh are extremely nutrient-dense and high in protein.

- Back of the Yards Algae Sciences uses algae to produce heme, an element that Impossible Foods use to make their plant-based meats taste, look, cook, and bleed like the real thing.

- AlgaeforFood uses fermentation to grow algae, and bio-refinery techniques to extract proteins, fibres, and lipids. They are utilized as ingredients for vegan fish fingers and others.

- Algama aims to improve food by choosing the most promising algae and turning them into useful ingredients. These substances can then be utilized as emulsifiers to create affordable, alluring, delicious, and sustainable substitutes for animal-based eggs, milk, and meat.

- Yemoja a marine ingredient start-up, claimed in 2021 that it would create a red microalgae formulation for plant-based burgers and steaks that would impart real, “bloody” juiciness.

By and Large

Although fungus and algae are not considered to be plants biologically, food made from plants that include fungi- and algae-based ingredients fall within our definition of “plant-based foods.” Plant-based meat is not defined as products like Meati’s steak that are manufactured entirely from fungi through fermentation procedures. Numerous high-protein beans, seeds, and grasses could substitute for various kinds of plant-based meat and fish. Furthermore, developing and economically growing innovative protein sources that use fewer resources than terrestrial plants (which need arable land and substantial inputs) is important. These sources potentially comprise fungi, other microbes, and both micro- and macro-algae. In your opinion are vegan meats are no longer considered to be plant-based if fungi or algae are added? Instead of being named plant-based meat, should they be called “algae-based meat” or “fungi-based meat”? Or do you believe it would be more accurate to label them as plant-based as they contain no components of animal origin?

References

ProFuture. A new and lighter Chlorella: ProFuture presents latest innovation. [online] Available at: https://www.pro-future.eu/news/a-new-and-lighter-chlorella-profuture-presents-latest-innovation

Allmicroalgae. Our Species of Microalgae Produced. [online] Available at: https://www.allmicroalgae.com/en/microalgae/

Daniel (2020). Allmicroalgae – Honey & White Chlorella vulgaris. [online] Allmicroalgae. Available at: https://www.allmicroalgae.com/en/2020/05/19/honey-white-chlorella-vulgaris/

Fu, Y., Chen, T., Chen, S.H.Y., Liu, B., Sun, P., Sun, H. and Chen, F. (2021). The potentials and challenges of using microalgae as an ingredient to produce meat analogues. Trends in Food Science & Technology, [online] 112, pp.188–200. doi:10.1016/j.tifs.2021.03.050. Available at: https://www.sciencedirect.com/science/article/abs/pii/S0924224421002429

foodhack.global. Algae Innovators From Alternative Meats To Milks, Discover 70 Algae Startups Companies Innovating With Algae | FoodHack. [online] Available at: https://foodhack.global/articles/algae-innovators-from-alternative-meats-to-milks-discover-70-algae-startups-companies-innovating-with-algae